The Bells of St. Helen's

by Mike Rickard

CONTENTS:

PHOTOGRAPHS:

This is the story of our bells and their journeys; journeys to and from their makers in Leicestershire separated by a century and a half; a journey through time as they pass down the tradition of church bell ringing from generation to generation of ringers and worshippers; and also, by their involvement in church services they mark the beginning of a journey into wedded life or the end of that journey at a funeral.

The pealing of church bells plays a part in most of our lives at some time and it Is important, maybe even our duty, to play our part in ensuring the continuation of a great tradition that has been entrusted to us by our ancestors and passing it on for the service and enjoyment of the community in the future.

Again, on behalf of the current band of ringers, thank you for your interest in our pastime and passion.

We hope you enjoy the story of St Helens church bells.

Pictured From Left to Right:

Back Row: Jaspar Wright; Mike Rickard. Middle Row: Bryan Boughton; Julia Boughton; Wendy Sisterson; Lucy Wright; Beverley Slade; Georgia Hales; Alan White.

Bottom Row: Jan Boughton; Lauren Hatcher.

Other current band members not pictured: Edna Hales; Jeff Cowling; Chris Burdett; Craig Palmer.

Back Row: Jaspar Wright; Mike Rickard. Middle Row: Bryan Boughton; Julia Boughton; Wendy Sisterson; Lucy Wright; Beverley Slade; Georgia Hales; Alan White.

Bottom Row: Jan Boughton; Lauren Hatcher.

Other current band members not pictured: Edna Hales; Jeff Cowling; Chris Burdett; Craig Palmer.

There are churches in England that have had bells since the 13th Century. Many (as here at St Helens) started with a single bell that was augmented over the years by adding one or two new bells at a time.

Originally bells would have been attached to a wooden headstock, with wrought iron spindles at each end suspended in bronze bearings. A lever and rope attached to the headstock allowed the ringer to swing the bell through a small arc, so that the clapper, hanging freely inside the bell, struck it at its thickest part near the lower edge. This style of ringing was known as swing chiming and was the primary technique adopted for several centuries.

Eventually it was realised that a bell could be swung higher by replacing the chiming lever with a quarter wheel. This not only increased the volume of sound but also exhibited the tonal qualities of the bell.

This principle was then further extended to the use of a complete wheel, which allowed the bells to be swung in slightly more than a full circle.

The now familiar basis of English-style full circle ringing in which a set of bells is rung in descending diatonic scale was now possible.

During the last couple of centuries church bell ringing has evolved into a pursuit which, apart from serving the church, develops a strong sense of community amongst its practitioners and a fascination which often lasts for life from the age of 9 or 10 years old.

Lauren, St Helens' current youngest ringer.

The majority of people will have heard the peal of bells ringing out across the neighbourhood from the church. Some people hate the “noise” because it disturbs their Sunday morning “lie in”. Others find the sound beautiful and it has become an integral part of celebrations for weddings and national victories, sadness at deaths and funerals and especially the summoning of worshippers to church on Sunday mornings.

In some parishes the number of people who practice bell ringing as a hobby that provides both physical and mental activity is unfortunately decreasing.

Against this current trend, we are proud of the fact that, at St Helens we are able to attract many youngsters who consider church bell ringing to be a wonderful and exciting pastime.

St Helens band boasts ringers from a wide range of ages. (Pictured are Alan, Georgia and Beverley)

Bell ringing is good fun and you will always be welcomed to visit other towers as part of the great network of bell ringers.

There are more than 5000 church towers In the U.K containing bells suitable for ringing and approximately 250 “peals” overseas, mostly in other English speaking countries (Australia, Canada, New Zealand, South Africa and U.S.A).

What’s more; learning to ring is entirely free! All that is required is commitment to regular attendance at the “band's” weekly practice and, when proficient, at Sunday service ringing.

Wendy and Jan keep an eye onthe "changes"

Being taught to ring by experienced ringers takes the form of two phases, the first being to learn to handle a bell competently and safely. This stage may take anything from a few weeks to six months according to an individual’s aptitude and time spent in the tower. The second stage involves the integration of the new ringer into “rounds” with fellow members of the band. This normally takes a few more months of concentrated effort at the beginning but the learning process is never ending.

Lucy concentrates hard to leam a new skill under the watchful eye of Jaspar.

The bells are rung manually and rotate full circle. Each bell is operated by a rope attached to the wheel on the supporting beam of the bell itself and the ringer controls the bell on the balance at the end of each revolution.

Church bells are large, ranging in weight from a few hundred pounds to several tons and a ring can consist of 4 - 12 bells. Bells are hung in strong frames of either oak or steel that allows them to swing through 360 degrees. The mechanism achieves such a good balance that youngsters and older ringers are able to control the largest bell with ease.

The usual arrangement of bells in the frame is such that their ropes hang in a circle in the ringing chamber below. Woven Into each rope is a tuft of brightly coloured wool (the sally), which marks the position where the ringer catches the rope while ringing.

Bells are rung from the “mouth up” position and with a pull of the rope, the bell swings through a full circle to the “up” position again and with the next pull it swings back in the other direction.

The practice of church bell ringing is more precisely referred to as “change ringing”, an English tradition started in the early part of the 17th Century, which has changed little since its evolution. Change ringing consists of ringing bells so that the order in which they sound is systematically changed.

The Bells are tuned to a normal (diatonic) scale and it is usual to start with ringing down the scale from the lightest (treble) to the heaviest (tenor), a sequence known as “rounds”.

Once a steady rhythm has been attained in "rounds” the order in which the bells sound Is then altered to give different sequences called “rows” or “changes”.

Changes may either be called out individually by the conductor, a style known as call change ringing or alternatively, made to a pre-set pattern known as “method ringing”.

In the latter, each ringer must learn that method in order to know when his or her particular bell must sound in each row.

The sequence then returns back to rounds to complete the session.

Call changes and a few standard methods with interesting names such as “Plain Hunt” and “Grandsire Doubles” are rung in most towers thus making it easy for visiting ringers to join in with other bands.

As ringers gain proficiency with experience there are many more advanced methods, which provide a continuing, challenge over time.

The ultimate test for experienced ringers is the ringing of “a peal” in which 5,000 or more changes are rung without breaks or repeats and lasting for about three hours.

The bell tower at St Helens is located at the west end of the church and contains a ring of eight bells which were cast by John Taylor Bellfounders in 1859/1860 at the order of the Reverend E.H.Lee.

Prior to 1859 the tower had contained a ring of six bells, one late Medieval bell (the first recorded single bell, hung in 1585), three other bells cast by Joseph Hatch in 1615 and 1630 and a treble and tenor bell cast by John and Christopher Hodson In 1670 and 1675 respectively.

The metal from these original bells was used in the making of a new ring of six, which left the foundry by canal boat on Sunday 12th June 1859 (Whitsunday) and was first rung on Monday 4th July of the same year.

A new Oak bell frame was manufactured by John Taylor at the same time and laid out for eight bells. Two new bells to complete the octave were cast on 17th July 1860, although for reasons unknown, they did not leave the works until Saturday 7th December 1861.

The bells were subsequently restored in 1923 by the now defunct bell hanging and bell founding partnership of Alfred Bowell & Sons of Ipswich.

At this restoration the original wooden headstocks were removed from the bells to facilitate the fitment of new metal headstocks.

Bowell also turned each of the eight bells presenting unworn surfaces of the sound bows (the thickest part near the lower edge where the clappers hit the bell).

The frame arrangement was also stiffened and modified in order to provide better rope fall.

The invoice for this work in 1923 was £190 with an additional sum of £15 for the provision of chiming apparatus (a separate campanile system allowing the playing of tunes on the bells). The final cost of the current works is expected to reach the staggering sum of £40,000!!!

It is interesting to bring the history of each bell into focus by considering world events that correspond with their individual installation dates.

1585 First bell (No. 3) by Giles Reve

• Just 20 years following the introduction of the Potato into Europe from South America

• 3 years later the Spanish Armada were defeated by the English

1615 No. 5 bell by Joseph Hatch

• 5 years before the Mayflower arrived in New England

• A year later William Shakespeare died

1630 No. 2 & No. 4 bells by Joseph Hatch

• King Charles II was born

• Dutch art was at it’s height with exponents such as Rembrandt and Rubens

1670 Treble (No. 1) by John Hodson

• Charles II of England and Louis XIV of France secretly signed a treaty in Dover ending hostilities between their Kingdoms

1675 No. 6 bell by John Hodson

• Just 12 years before Isaac Newton’s book Principia was published containing theories that continue to shape our understanding of the laws of Physics today

• The construction of the Royal Observatory at Greenwich began as Charles II laid a foundation stone

1859 6 No. bells recast by John Taylor

• Big Ben’s bell was activated

• Charles Darwin’s book Origin of the species published

1861 2 No. new Trebles by John Taylor

• Charles Dickens wrote the novel Great Expectations

• The outbreak of the American Civil War

• 2 years later the first underground railway opened in London

1923 Refurbishment by Alfred Bowell

• Just 3 years after the first general radio broadcasts in UK and USA

• 1 year before the death of Lenin

On Wednesday 7th August 2002 an engineer from John Taylor Bellfounders undertook a full survey of the bell frame, bells and fittings.

John Taylor was the company that recast the original six bells from the tower in 1859 and added a further two in 1860.

The oak frame itself, as installed in 1859 and strengthened in 1923, was found to be in sound condition and the engineer stated in his report that “ I consider that the bell frame has many years of good life in it yet".

It was simply recommended that the frame timbers be thoroughly treated with an appropriate preservative containing both insecticide and fungicide therefore guaranteeing longevity of the timber members.

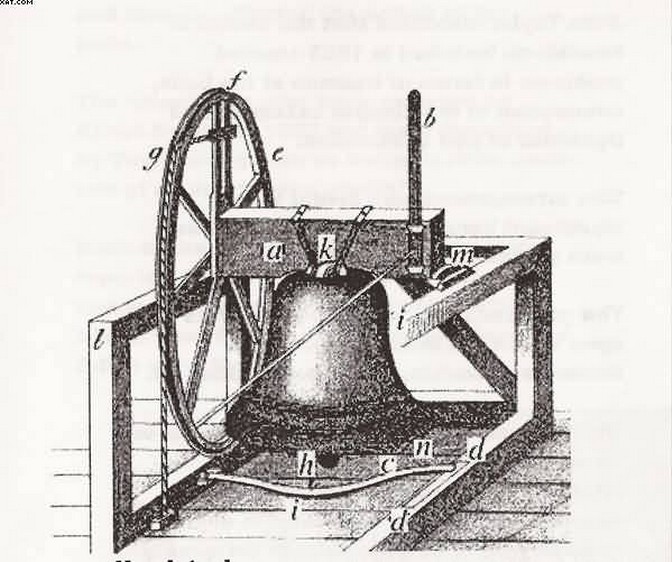

The following illustration shows the primary parts of a typical bell arrangement as a means of identifying each appropriate recommendation made by the engineer.

a - Headstock b - Stay c - Up of bell d - Blocks e - Wheel f - Groove g - Garter hole h - Clapper I -Slider k - Cannons I - Frame m - Gudgeons n - Sound bow

John Taylor Identified that the design of headstock installed in 1923 created problems In terms of balance of the bells, connection of the clapper assembly and tightness of bolt assemblies.

This arrangement also meant that significant bending and shearing forces were placed upon the bell bolts.

The gudgeons and bearings (the pivots upon which the bells turn) showed evidence of working loose and leaking oil.

Whilst these symptoms were considered to be normal wear and tear after an intervening period of 80 years, they were nevertheless, expected to lead to a relatively rapid deterioration in the quality of striking and swing of the bells.

All of the clappers were flattened and starting to laminate after many years of wear and the crownstaples (the parts securing the clappers to the bells) were similarly wearing.

The rope pulleys were worn and the action of the ropes over the years had formed grooves in the timber pulley wheels, which resulted In increased friction during ringing and thereby affected the action of the bells.

The wheels had also been replaced by Alfred Bowell In 1923 and were described by Taylor's engineer as being “a little crude and of an unorthodox profile’'.

Each of the sliders and their tracks were reported as being worn at their ends and congealed through grease and oil, which had exuded from the gudgeon bearings and fallen upon them.

One of the bells in need of a little refurbishment.

As a result of the foregoing observations John Taylor’s engineer concluded that....”although the bells are by no means in an un-ringable state, I am quite certain that the condition of their fittings and particular the bearing assemblies means that they are going to deteriorate on a relatively rapid basis over the next 5-10 years. The church therefore, needs to consider a major restoration project”

The engineer recommended that the eight bells be removed from the tower and transported to the bell foundry to provide the following restoration;

(i) Turning of the bells to present unworn surfaces of their sound bows to the blows of the clappers.

(ii) Tuning of the bells to set them into a proper scale relationship and to enable the tones of the bells to be released resulting in “a more musical aspect”.

It was further recommended that new hollow box section cast Iron headstocks of curved section be fitted to the bells to bring their centres of gravity nearer to the pivot points.

The gudgeons and bearing assemblies were recommended for replacement by heavy duty, self-aligning ball bearing assemblies utilising sealed lubricated units.

Other fittings recommended for replacement were timber elements in the

form of: -

(i) Hardwood wheels

(ii) Stays

(ill) Sliders

(iv) Rope rollers working on sealed ball bearings and boxed in to protect the bell ropes.

These recommendations indeed represented, as John Taylor’s engineer reported, “major restoration” of the bells and fittings.

(ii) Stays

(ill) Sliders

(iv) Rope rollers working on sealed ball bearings and boxed in to protect the bell ropes.

These recommendations indeed represented, as John Taylor’s engineer reported, “major restoration” of the bells and fittings.

However, the project would mean that further (and possibly irreversible) deterioration of the bells would be halted and ensure the passing on of the long tradition of church bell ringing at St Helens church to future generations in the parish.

Following the engineer’s report It was agreed to include refurbishment of the bells In the SHINE (St Helens Is Never Ending) £300,000 fundraising project set up to facilitate major repairs to St Helens Church.

Thanks to the tireless efforts of SHINE and generous donations from kind benefactors the PCC were eventually able to announce that the refurbishment could proceed.

The final rounds before removal of the bells were rung out across the Parish on Sunday 5th March 2006. The following week saw enabling works being carried out by members of the band of ringers In the bell tower to allow the bells to be removed.

At 9.00 a.m. on Saturday 11th March 2006 a team led by the Bell Restoration Subcommittee of the Kent County Association of Change Ringers and aided by a number of local volunteers commenced the removal of the bells.

Bryan Boughton, the Band’s Captain prepares the bells for removal.

Starting with the tenor bell (being the largest and heaviest), the bells were hoisted clear of their mountings by means of chains and blocks suspended from timber beams in the roof of the tower. Each bell was then gently lowered down through hatches in the floors of the Bell Chamber, Clock Chamber and Ringing Chamber respectively.

The tenor bell is lowered through the hatch of the Bell Chamber.

Finally, at around 11.00 a.m. a packed St Helens gasped as the tenor bell descended through the ceiling of the ground floor beneath the tower for the first time in a century and a half.

All those congregated in the church and those involved in the removal of the bells realised that they were witnessing history in the making.

Excited onlookers watch the last few feet of the bell’s descent.

Each bell was lowered onto wooden pallets and removed by pallet handler through the large north door of the church. Each bell that is except the tenor, which was too big to go through even this huge door!

Following a great deal of deliberation a plan was devised to raise the pallet assembly so that the tenor bell could be raised above the steps leading to the porch and out through the main entrance to the church.

Some delicate skilful manoeuvring of the pallet handler from Inside and a forkllft from outside of the church eased the bell through the porch gates with no more than half an inch to spare.

The forkllft removed each individual bell to a truck and then to Buckland Farm to await transportation to the John Taylor bell foundry.

A bell sees daylight for the first time in 150 years.

The Tuesday following their removal saw the eight bells on the road travelling back to their makers utilising a slightly different mode and speed of transport than when they first came down to Cliffe.

Rolling up the M1 on a diesel-powered lorry organised by Shepherd Neame, the journey would have taken a matter of a few hours (even allowing for the M25I).

Back in 1859 the reverse journey commenced from John Taylor’s works by canal boat.

John Taylor Bellfounders continues a line of bellfounding that has been unbroken since the middle of the 14th Century, when a Bellfounder called Johannes de Stafford was active only 10 miles from the site of the present foundry.

Since 1784 the business has been in the hands of the Taylor family and is now proud to operate the largest bell foundry in the World.

John Taylor settled in their current premises in Loughborough in 1859 and the St Helens Bells were In fact the first bells cast at the new foundry.

Everyone at John Taylor therefore, considered St Helens bells to be the “Stars of the Show” upon their return after 150 years.

This interesting fact came to light during a visit to the foundry by members of the bellringers and congregation on 4th May 2006.

Jill and Robert greet the “Stars of the Show” during a visit to the foundry.

Products made in the John Taylor Bellfoundry have been exported all over the World and the largest bell in Britain, “Great Paul” at St Paul’s Cathedral in London and weighing In at 17 tons was cast in Loughborough in 1881.

In comparison, St Helen’s heaviest bell, the tenor, might be considered a “lightweight” but still tips the scales at 14 cwt or approximately three quarters of a ton.

Whilst the bells were away members of our band of ringers carried out preparation of the bell frame and Ringing Chamber.

The bell frame has been cleaned and treated with preservative in order to ensure its integrity for another 150 years and the Ringing Chamber will be re-decorated for the first time since 1973.

Visitors from St Helens Church at the foundry

With the bells returned and shortly to be heard ringing across the parish again one may reflect on the fantastic achievement represented by the refurbishment.

A major project of this kind does not happen without the involvement of many people and a record of events such as this booklet represents would be Incomplete without acknowledging their generosity.

Many individual and corporate benefactors have kindly donated funds and the fact that you have purchased and are reading this means that you are one of those.

Others have given their time and efforts towards the organisation of numerous ingenious fundraising schemes over many years.

Some have helped to keep the costs of the project to a minimum by assisting with the removal, preparation for and re-installation of the bells.

Without all of these folk the project could not have taken place and the bells of St Helens may have deteriorated to a condition where they would have been unringable. However, in acknowledging the magnificence of the current project, one should also express gratitude to the bellringers and church members of past generations.

This current refurbishment, as we have read, Is not the first project that has been carried out to allow the tradition of church bell ringing to continue at St Helens. Indeed, the 1859-1861 project would have represented an even greater physical and financial challenge to the parish.

The legacy of our former peers has been passed down to us over more than 400 years and everyone Involved in this project can be proud that our bells may now continue to ring out to the glory of God for many generations to come.

© 2006, Mike Rickard